bending steel sheet metal Improve your sheet metal bending techniques with these 8 design guidelines. Learn how to create precise bends and avoid costly mistakes. Buy Zig Zag Sheet Metal Silver Forming Former Jewelry Rolling Corrugating .

0 · types of bending sheet metal

1 · sheet metal bending standards

2 · sheet metal bending near me

3 · sheet metal bending guidelines

4 · sheet metal bending chart

5 · problems with sheet metal bending

6 · bending sheet metal by hand

7 · bending galvanized sheet metal

ZINCALUME® steel is one of the world’s leading Al-Zn alloy coated steel ideal for roofing, wall cladding and manufacturing alternate applications. Metallic coating of ZINCALUME® steel combines the corrosion protection of aluminium with sacrificial protection of zinc that enhances corrosion resistance and gives significantly longer service .

types of bending sheet metal

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake. See moreThis Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending . Finding the minimum bend radius for steel or aluminum plate requires a little research. Learn how to bend metal and about bending steel plate and aluminum.

In air bending, the punch pushes on the sheet metal that is resting on the die's opening. We usually use a press brake for V bending because the sheet metal does not touch the bottom of . Improve your sheet metal bending techniques with these 8 design guidelines. Learn how to create precise bends and avoid costly mistakes.

custom aluminum machining parts wholesale

Sheet metal bending is the forming of metal into different geometries, by using a force to deform the metal. It is referred to as sheet metal bending as a thin sheet of metal is bent once, or multiple times, to form the . Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake.

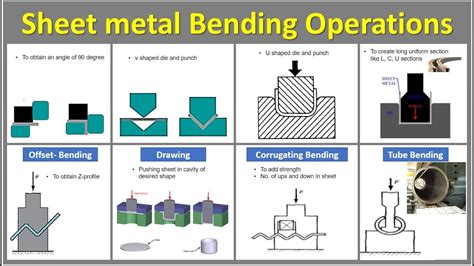

This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending and material selection information. Finding the minimum bend radius for steel or aluminum plate requires a little research. Learn how to bend metal and about bending steel plate and aluminum. Bending is one of the most common sheet metal fabrication operations. Also known as press braking , flanging, die bending, folding and edging , this method is used to deform a material to an angular shape.

Sheet metal bending is a fundamental forming process that alters the geometry of a metal sheet or panel by creating angular changes along a linear axis.In air bending, the punch pushes on the sheet metal that is resting on the die's opening. We usually use a press brake for V bending because the sheet metal does not touch the bottom of the die. (A press brake is a simple machine used in sheet metal bending. It holds the sheet metal in place so the punch and die can bend it into the shape we want.) Improve your sheet metal bending techniques with these 8 design guidelines. Learn how to create precise bends and avoid costly mistakes. Sheet metal bending is the forming of metal into different geometries, by using a force to deform the metal. It is referred to as sheet metal bending as a thin sheet of metal is bent once, or multiple times, to form the final geometry. The thickness of sheet metal used can vary.

Bending sheet metal is a meticulous process. It involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make the bend.

Sheet metal bending is a pivotal process in the realm of metal fabrication, transforming flat sheets into angular, complex structures through precise deformation. It's fascinating how a simple concept, bending, can be so integral in shaping components for myriad industries, from automotive to aerospace. Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake.This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending and material selection information. Finding the minimum bend radius for steel or aluminum plate requires a little research. Learn how to bend metal and about bending steel plate and aluminum.

Bending is one of the most common sheet metal fabrication operations. Also known as press braking , flanging, die bending, folding and edging , this method is used to deform a material to an angular shape. Sheet metal bending is a fundamental forming process that alters the geometry of a metal sheet or panel by creating angular changes along a linear axis.In air bending, the punch pushes on the sheet metal that is resting on the die's opening. We usually use a press brake for V bending because the sheet metal does not touch the bottom of the die. (A press brake is a simple machine used in sheet metal bending. It holds the sheet metal in place so the punch and die can bend it into the shape we want.)

Improve your sheet metal bending techniques with these 8 design guidelines. Learn how to create precise bends and avoid costly mistakes. Sheet metal bending is the forming of metal into different geometries, by using a force to deform the metal. It is referred to as sheet metal bending as a thin sheet of metal is bent once, or multiple times, to form the final geometry. The thickness of sheet metal used can vary.

sheet metal bending standards

sheet metal bending near me

Bending sheet metal is a meticulous process. It involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make the bend.

curso mecanizado cnc

Small Metal Sheet %240 in quantities of 0 to 8 in metal_shelves Containers. ↓ Approximate spawn chance in garagestorage Areas ↓. Small Metal Sheet %240 in quantities of 0 to 8 in counter Containers. Small Metal Sheet %279 in quantities of 0 to 9 in crate Containers. Small Metal Sheet %240 in quantities of 0 to 8 in metal_shelves ContainersMetal sheet barricades block line of sight, metal bars do not. Three materials can be used to create barricades: wooden planks, metal sheets, and metal bars. With one of these .

bending steel sheet metal|sheet metal bending chart