spring back in sheet metal forming Have you ever wondered why some sheet metal parts don't fit perfectly after bending? This article explores the perplexing issue of springback in sheet metal processing. Learn how springback affects part accuracy and . Buy sheet metal parts in bulk online from 56 verified wholesale sheet metal parts suppliers, manufacturers (OEM, ODM & OBM), distributors, and factory lists on Global Sources.

0 · springback sheet metal problems

1 · springback sheet metal case study

2 · springback sheet metal bending

3 · springback bending techniques

4 · springback bending process

5 · sheet metal forming process

6 · aluminum springback strength

7 · air forming zone springback

Smartlathe is specialized in designing and building CNC slant bed lathes. As a saying goes, there is no “one size fits all” when it comes to CNC machine tools. Different turning parts have different process requirements, and we will use our rich experience to tell you what numerical control lathe is the most suitable.

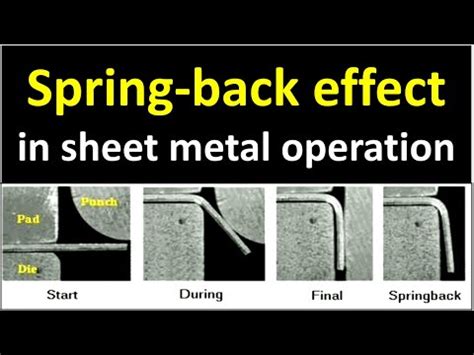

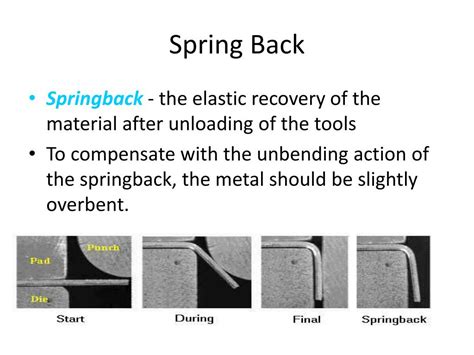

The spring-back phenomenon happens when sheet metal attempts to return to its original shape after bending or deformation. Once the bending force is removed, the metal springs to its initial shape. Metal’s elastic recovery can cause it to . Have you ever wondered why some sheet metal parts don't fit perfectly after bending? This article explores the perplexing issue of springback in sheet metal processing. Learn how springback affects part accuracy and .For a given part shape and sheet thickness, the springback occurring when using AHSS grades is greater than that experienced in mild or conventional HSLA steels. The magnitude of . Springback is inherent in sheet metal forming. It can be can be understood by looking at a material’s stress stain curve (discussed in the module on Tensile Testing) which .

Blank holder helps prevent wrinkling and reduces springback. Blank holder not necessary if blank diameter / blank thickness is less than 25-40. Smaller values for deeper forming. .Spring back occurs when a metal is bent and then tries to return to its original shape. There are two basic views as to why Spring Back occurs, one states that it is due to the displacement of molecules and the other considers Spring Back .Springback is the recovery of the elastic stresses induced during the metal forming process. Once a sheet of metal plastically deforms to a given shape by a forming tool, the final shape of the sheet is subject to change as soon as the . This paper introduces a new method on cold metal forming of a circular metal tube into a structural profile and analyzes the process by theoretical and experimental methods.

Spring-back is one of the most sensitive features of sheet metal forming processes because the elastic recovery during unloading leads to some geometric changes in the product. Sheet metal deformation is purely an implementation of Stress-Strain curve characteristics. Spring back in Sheet Metals. When a part is released from the forces of the forming tool at the end of the operation, springback is the geometric modification made to the part. The sheet metal forming process, in theory, can be viewed as relatively straightforward operation where a sheet of material is plastically deformed into a desired shape. . T.-L. Lin, Use of a coupled explicit–implicit solver for calculating spring back in automotive body panels, Livermore Software Technology Corporation, Livermore, CA, 1992 .

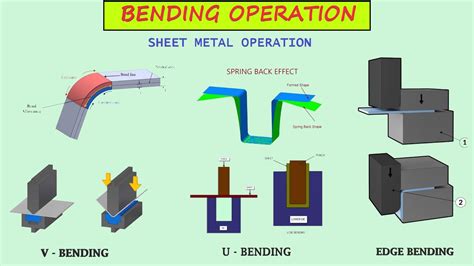

Sheet Metal Forming 2.810 D. Cooper !“Sheet Metal Forming” Ch. 16 Kalpakjian !“Design for Sheetmetal Working”, Ch. 9 Boothroyd, Dewhurst and Knight . Examples-sheet metal formed . Female die Male die (punch/post) . Low spring back Al. 5052 H32 (10.6E6psi) pressure is removed. This r elea se of energy is the dr iving force for spring-back of sheet metal forming [1]. In . this forming operation, .Due to the fact the sheet metal work hardens during forming/drawing, it is desirable to stretch a sheet metal part as much as possible to increase part strength, and thereby increase the rigidness of the part and lessen the effect of springback. Stretch forming is often a more effective solution to springback problems than direct compensation.

Spring back Effect | Definition | Sheet metal | ENGINEERING STUDY MATERIALSSpringback is the geometric change made to a part at the end of the forming proces. Metal parts that spring back excessively after forming won’t have the right shape, which means that different parts won’t fit together properly during assembly. . Further, because of differences from machine to machine and from piece to piece, springback compensation during sheet metal forming can be a frustrating and expensive exercise . Spring-back is a very common and critical phenomenon in sheet metal forming operations, which is caused by the elastic redistribution of the internal stresses after the removal of deforming forces.After a bending operation, residual stresses will cause the sheet metal to spring back slightly. Due to this elastic recovery, it is necessary to over-bend the sheet a precise amount to acheive the desired bend radius and bend angle. The final bend radius and bend angle can be approximated from the sheet thickness, K-factor, material yield .

springback sheet metal problems

Sheet metal forming is one of the most important manufacturing processes applied in many industrial sectors, with the most prevalent being the automotive and aerospace industries. The main purpose of that operation is to produce a desired formed shape blank, without any material failures, which should lie well within the acceptable tolerance limits. Springback is .Calculating Spring Back. The spring bacK-Factor, commonly denoted by Ks, is the relation between the initial and final angles. A spring bacK-Factor of Ks=1 means there is no Spring Back, where a value of 0 means total Spring Back. To calculate the spring bacK-Factor ahead of a test piece it is important to understand that the bend radius is . Sheet-metal forming is one of the most important manufacturing processes in the automotive industry. This study proposes a multiobjective optimisation scheme that controls both sheet-metal formability and springback. First, the mechanical properties of DP590 steel were characterised to obtain the mechanical parameters and forming limit diagram (FLD) of DP590. . This project is basically an investigation of springback behavior during sheet metal forming process on different parameters by using numerical method. Non linear numerical simulation was performed by using finite element commercial ABAQUS/CAE software. Two different parameters were used in the simulation, which is the material type of sheet .

The spring-back simulation of sheet metal forming for the HT-7U vacuum vessel has been performed using an elastic–plastic nonlinear finite element code. From the simulation process it has shown that it is vital to the design of the forming tools used in the sheet stamping operation. This work is a an iteration process in which some spring .

Immediately after forming, the specially designed water-cooled die uniformly chills the stamping to produce a microstructure of hard martensite with yield strengths of about 170 Ksi. The as-received total elongation of 25 percent decreases to 6 percent due to the higher post-quench strength. The hot-forming process achieves two key benefits.

Fig. 5 Experimental data and simulation results of spring-back angle after unloading at different punch stroke in a V-bending process E. Effect of punch radius, punch angle and die-lip radius W.M. Chan [10] also focused on Finite element analysis of spring-back of V-bending sheet metal forming processes The most prominent feature of sheet metal forming process is an elastic recovery phenomenon during unloading which leads to spring-back and sidewall curl. Accordingly, it has been a crucial research subject for designing bending tools .

For purposes of this review, springback is the elastically driven change of shape of a metal sheet during unloading and following forming. Scientific advances related to this topic have accelerated dramatically over roughly the last decade, since the publication of two reviews in the 2004–2006 timeframe (Wagoner, 2004, Wagoner et al., 2006).The current review focuses on . Request PDF | Experimental and finite element analysis of spring back in sheet metal forming | This paper presents an experimental and numerical study of 2D draw bend spring back phenomenon .

The paper [4] works on reducing spring back, economical realization, . The occurrence of the buckling in sheet metal forming is an important problem for efficient press shop operations.

Abstract In this study mathematical analysis of spring back was done for optimization of sheet metal bending process. The influence of sheet metal thickness, sheet metal type, friction, tool .

And the conclusion is drawn: in the future, multi-point forming of sheet metal using high-frequency ultrasonic excitation for springback control during the forming process coupled with artificial intelligence for springback compensation control will be a promising research direction for controlling springback in the multi-point forming of sheet .SHEET METAL FORMING PROEFSCHRIFT ter verkrijging van de graad van doctor aan de Universiteit Twente, op gezag van de rector magnificus, prof. dr. W.H.M. Zijm, volgens besluit van het College voor Promoties in het openbaar te verdedigen op donderdag 22 mei 2008 om 13.15 uur. door Igor Alexandrovich Burchitz geboren op 21 november 1976 te .Sheet Metal Forming: Spring-back of hydro mechanical deep drawn parts Authors: Jens Buchert, University of Applied Sciences, Aalen, Germany . Figure 3: Parameters which influence the spring-back behaviour Metal Forming I 4th European LS-DYNA Users Conference E– I- 38. In this case the spring-back simulations are not comparable; the .

Sheet metal forming processes are widely used in the automobile industry. The most frequently used techniques are bending, stretching, stamping and other. In these sheet metal forming processes, defects such as rupture, wrinkling, galling and springback in formed parts might occur, whether during or after the process. Incremental sheet forming (ISF) has the potential to meet modern demands of rapid, flexible, and relatively low-cost manufacturing of small batches of sheet metal products. However, the adoption of the ISF process in industry is largely hampered by its limited geometric accuracy caused by multiple sources, e.g., tool compliance, addressed in .

ornamental and miscellaneous metal fabrication magazine

springback sheet metal case study

Founded in Salt Lake City, Utah in 2021, THECNCSOURCE is a veteran owned .

spring back in sheet metal forming|springback bending techniques