cnc machine 3d printed parts When to CNC Machine Your 3D Printed Parts Computerized numerical control . Below are the most common types of shade structures and their unique features for any kind of project: 1. Cantilever Shade Structures. Cantilever shade structures have a post system that minimizes column obstruction, leaving more open space beneath the shade. In these structures, the posts — typically two — are positioned in the back.

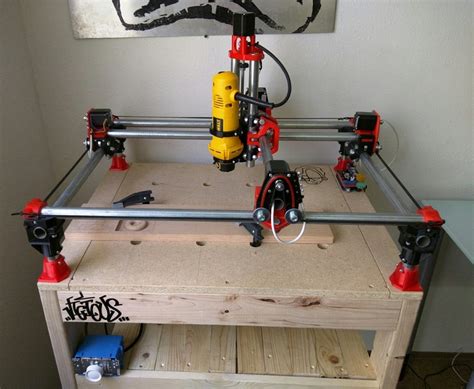

0 · mostly 3d printed cnc

1 · convert 3d printer to cnc

2 · best 3d printer for cnc

3 · 3d printing milling machine

4 · 3d printer diy cnc milling

5 · 3d printer diy cnc lathe

6 · 3d printed cnc router plans

7 · 3d printable cnc machine

But don’t worry: Most electrical boxes fall into nine main types, specializing in a load rating tailored to specific tasks and electric appliances. 1. Metal and Plastic Electrical Boxes. The majority of electric boxes are metal or plastic. Most indoor metal boxes are steel, while indoor plastic boxes are PVC or fiberglass.

Improve the accuracy and speed of your 3D printed parts with CNC machining. Contact Stratasys Direct for 3D printing machining part services.When to CNC Machine Your 3D Printed Parts Computerized numerical control . If 3D printing is the most efficient way to produce a given part – say a prototype – but CNC machine tools provide more accurate results, then printing rough dimensions with a 3D printer and machining precisely with a CNC .For further streamlining, the LDO Milo V1.5 CNC Kit Bundle offers a seamless foundation for your DIY-CNC experience by providing all essential hardware, .

mostly 3d printed cnc

convert 3d printer to cnc

The PrintNC is a high performance, DIY CNC router. It's based on a steel frame to ensure rigidity and uses 3D printed parts to make assembly easy. First launched in late 2019, there are now hundreds of PrintNC builds around the .G300 - 3D Printed CNC Machine: About 6 months ago I started designing a cnc machine that allowed me to carry out some milling works; the design phase was very demanding in terms of .

Is 3D printing or CNC machining better for your custom part applications? Learn the practical differences between CNC machining and 3D printing and how to select the right technology for manufacturing prototypes, end-use parts and .

Advanced finishing tools and long reach, tapered tools from brands like Harvey Tool can easily machine the tight geometries of 3D printed parts, while extremely sharp diamond-coated tooling and material-specific tools .

Improve the accuracy and speed of your 3D printed parts with CNC machining. Contact Stratasys Direct for 3D printing machining part services. If 3D printing is the most efficient way to produce a given part – say a prototype – but CNC machine tools provide more accurate results, then printing rough dimensions with a 3D printer and machining precisely with a CNC machine can make perfect sense.For further streamlining, the LDO Milo V1.5 CNC Kit Bundle offers a seamless foundation for your DIY-CNC experience by providing all essential hardware, 3D printed parts, and expert assistance to assemble your own Millenium Machines Milo V1.5 CNC mill.

The PrintNC is a high performance, DIY CNC router. It's based on a steel frame to ensure rigidity and uses 3D printed parts to make assembly easy. First launched in late 2019, there are now hundreds of PrintNC builds around the world, with makers using them to build projects from wood, aluminium, steel, carbon fiber, and many other materials.

G300 - 3D Printed CNC Machine: About 6 months ago I started designing a cnc machine that allowed me to carry out some milling works; the design phase was very demanding in terms of time because it involved both the mechanical and the electronic parts. I decided to call this mac.Is 3D printing or CNC machining better for your custom part applications? Learn the practical differences between CNC machining and 3D printing and how to select the right technology for manufacturing prototypes, end-use parts and everything in between. Advanced finishing tools and long reach, tapered tools from brands like Harvey Tool can easily machine the tight geometries of 3D printed parts, while extremely sharp diamond-coated tooling and material-specific tools designed for plastics and composites can work to create a beautiful, in-tolerance finished part regardless of the material. Check out these 3D printed CNC devices that can take your home workshop to the next level.

This guide goes through all the steps to build your own CNC machine from scratch. It includes a complete bill of materials (BOM), STL/OBJ-files for all the 3d-printed parts and detailed instructions of how everything is assembled. It also includes instructions of how all the necessary open-source softwares are installed.Root CNC used 3D printed parts to provide accurate assembly of the machine and easy the build process. It is scalable – make the machine any size you want, to fit your application. Its Open Source – built and controlled via open source hardware and software. Root CNC shall continue to work and develop its machines across the multiple platforms. Improve the accuracy and speed of your 3D printed parts with CNC machining. Contact Stratasys Direct for 3D printing machining part services.

best 3d printer for cnc

If 3D printing is the most efficient way to produce a given part – say a prototype – but CNC machine tools provide more accurate results, then printing rough dimensions with a 3D printer and machining precisely with a CNC machine can make perfect sense.

For further streamlining, the LDO Milo V1.5 CNC Kit Bundle offers a seamless foundation for your DIY-CNC experience by providing all essential hardware, 3D printed parts, and expert assistance to assemble your own Millenium Machines Milo V1.5 CNC mill.The PrintNC is a high performance, DIY CNC router. It's based on a steel frame to ensure rigidity and uses 3D printed parts to make assembly easy. First launched in late 2019, there are now hundreds of PrintNC builds around the world, with makers using them to build projects from wood, aluminium, steel, carbon fiber, and many other materials.

G300 - 3D Printed CNC Machine: About 6 months ago I started designing a cnc machine that allowed me to carry out some milling works; the design phase was very demanding in terms of time because it involved both the mechanical and the electronic parts. I decided to call this mac.

Is 3D printing or CNC machining better for your custom part applications? Learn the practical differences between CNC machining and 3D printing and how to select the right technology for manufacturing prototypes, end-use parts and everything in between. Advanced finishing tools and long reach, tapered tools from brands like Harvey Tool can easily machine the tight geometries of 3D printed parts, while extremely sharp diamond-coated tooling and material-specific tools designed for plastics and composites can work to create a beautiful, in-tolerance finished part regardless of the material. Check out these 3D printed CNC devices that can take your home workshop to the next level.This guide goes through all the steps to build your own CNC machine from scratch. It includes a complete bill of materials (BOM), STL/OBJ-files for all the 3d-printed parts and detailed instructions of how everything is assembled. It also includes instructions of how all the necessary open-source softwares are installed.

If you install a box in a wet location, for example, you must use a box, fittings, and installation methods that are acceptable for wet locations. Fortunately, Art. 314 helps you select the right outlet, device, and junction boxes — and size them properly.

cnc machine 3d printed parts|3d printer diy cnc milling