a metal stamping machine can process 34 sheets To arrive at this, we need to divide the total quantity of items to be worked on by the processing rate of the machine. In our case, this would be 3,128 (total items) divided by 34 (processing . S&W .38 Military & Police Revolver Box Description: Gold 2 piece box with metal corners all intact. Marked for nickel finish square butt with 5 inch barrel. SOLD

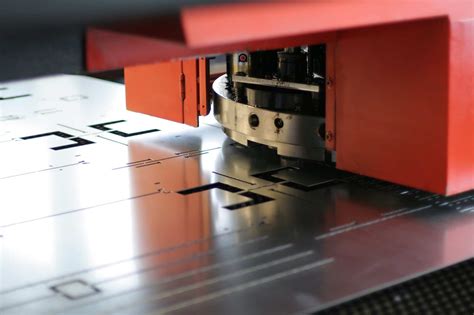

0 · The Metal Stamping Process: Techniques and Applications

1 · Sheet Metal Stamping: A Complete Guide

2 · Sheet Metal Stamping Process Explained

3 · Question 1 of 10:a Metal Stamping Machine Can Process 34

4 · Operations Management Math Quiz Question 10 of 10 a Metal

5 · Metal Stamping 101

6 · Guide to Sheet Metal Stamping

7 · DV11PUB9

8 · A metal stamping machine can process 34 sheets of metal per

Wesco Distribution is located at 225 W Station Square Dr #700 in Pittsburgh, Pennsylvania 15219. Wesco Distribution can be contacted via phone at 412-454-2200 for pricing, hours and directions. Contact Info

QUESTION 1 of 10:A metal stamping machine can process 34 sheets of metal per hour.You have 3,158 sheets of metal to process.How many hours will it take to process all of them? a) 92 b) .【Solved】Click here to get an answer to your question : Operations Management .

【Solved】Click here to get an answer to your question : Operations Management Math Quiz QUESTION 10 of 10 A metal stamping machine can process 34 sheets of metal per hour.You .To arrive at this, we need to divide the total quantity of items to be worked on by the processing rate of the machine. In our case, this would be 3,128 (total items) divided by 34 (processing .Sheet metal stamping is one of the techniques crucial to our success. We’ll explore this vital technique together. The sheet metal stamping process is where metal sheets can be shaped and sized to the desired shape or size by .understanding of the stamping process and the die systems used to form sheet metal. • the terms “ductility” and “formability” are explained • the essential components of the stamping process .

The Metal Stamping Process: Techniques and Applications

The stamping process in sheet metal involves several key steps to transform flat sheets into shaped components. It begins with designing the part and creating custom tooling, including .There are basically only three components to sheet metal stamping—the sheet metal, die, and press machine—but any single part can require multiple steps to arrive at its final form. The following guide explains a few common processes . “Metal stamping machines may do more than just stamping; they can cast, punch, cut and shape metal sheets. Machines can be programmed or computer numerically controlled .

sheet metal cnc

Sheet metal stamping involves using dies and presses to transform flat metal sheets into desired shapes and forms. The process starts with designing custom dies, typically made from hardened steel or carbide, with a .QUESTION 1 of 10:A metal stamping machine can process 34 sheets of metal per hour.You have 3,158 sheets of metal to process.How many hours will it take to process all of them? a) 92 b) 128 c) 342 d) 444.【Solved】Click here to get an answer to your question : Operations Management Math Quiz QUESTION 10 of 10 A metal stamping machine can process 34 sheets of metal per hour.You have 3,128 sheets of metal to .To arrive at this, we need to divide the total quantity of items to be worked on by the processing rate of the machine. In our case, this would be 3,128 (total items) divided by 34 (processing rate) which equals to approximately 92 hours.

Sheet Metal Stamping: A Complete Guide

Sheet metal stamping is one of the techniques crucial to our success. We’ll explore this vital technique together. The sheet metal stamping process is where metal sheets can be shaped and sized to the desired shape or size by applying an external force. Stamping machines and dies are used to achieve this. It’s fascinating.understanding of the stamping process and the die systems used to form sheet metal. • the terms “ductility” and “formability” are explained • the essential components of the stamping process are detailed • basic stamping terms are defined • progressive and transfer die technology is illustratedThe stamping process in sheet metal involves several key steps to transform flat sheets into shaped components. It begins with designing the part and creating custom tooling, including dies tailored for precision and repeatability.

There are basically only three components to sheet metal stamping—the sheet metal, die, and press machine—but any single part can require multiple steps to arrive at its final form. The following guide explains a few common processes that might occur during metal stamping. “Metal stamping machines may do more than just stamping; they can cast, punch, cut and shape metal sheets. Machines can be programmed or computer numerically controlled (CNC) to offer high precision and repeatability for each stamped piece.

Sheet metal stamping involves using dies and presses to transform flat metal sheets into desired shapes and forms. The process starts with designing custom dies, typically made from hardened steel or carbide, with a negative impression of the desired part shape. Sheet metal stamping is the process of transforming sheets of metal material into a useful component or part. During the process, metal is fed into a press where a stamping tool, referred to as a die, presses through or into the metal with great force to create the desired shape.

QUESTION 1 of 10:A metal stamping machine can process 34 sheets of metal per hour.You have 3,158 sheets of metal to process.How many hours will it take to process all of them? a) 92 b) 128 c) 342 d) 444.

【Solved】Click here to get an answer to your question : Operations Management Math Quiz QUESTION 10 of 10 A metal stamping machine can process 34 sheets of metal per hour.You have 3,128 sheets of metal to .

To arrive at this, we need to divide the total quantity of items to be worked on by the processing rate of the machine. In our case, this would be 3,128 (total items) divided by 34 (processing rate) which equals to approximately 92 hours.

Sheet metal stamping is one of the techniques crucial to our success. We’ll explore this vital technique together. The sheet metal stamping process is where metal sheets can be shaped and sized to the desired shape or size by applying an external force. Stamping machines and dies are used to achieve this. It’s fascinating.understanding of the stamping process and the die systems used to form sheet metal. • the terms “ductility” and “formability” are explained • the essential components of the stamping process are detailed • basic stamping terms are defined • progressive and transfer die technology is illustratedThe stamping process in sheet metal involves several key steps to transform flat sheets into shaped components. It begins with designing the part and creating custom tooling, including dies tailored for precision and repeatability.There are basically only three components to sheet metal stamping—the sheet metal, die, and press machine—but any single part can require multiple steps to arrive at its final form. The following guide explains a few common processes that might occur during metal stamping.

sheet metal buck

“Metal stamping machines may do more than just stamping; they can cast, punch, cut and shape metal sheets. Machines can be programmed or computer numerically controlled (CNC) to offer high precision and repeatability for each stamped piece. Sheet metal stamping involves using dies and presses to transform flat metal sheets into desired shapes and forms. The process starts with designing custom dies, typically made from hardened steel or carbide, with a negative impression of the desired part shape.

Sheet Metal Stamping Process Explained

sheet metal building homes

sheet metal car body

Welding thin metal poses a unique set of challenges, requiring a delicate balance between heat application and precision to avoid warping or burn-through. Whether you’re working with sheet metal, thin tubing, or other lightweight materials, the key to successful welding lies in mastering the nuances of technique and equipment settings.

a metal stamping machine can process 34 sheets|Sheet Metal Stamping Process Explained