sheet metal forming process ppt Sheet Metal Forming Sheet metal forming is a process that materials undergo . Contact - TreehouseBrackets.com

0 · sheet metal stamping process pdf

1 · sheet metal processes pdf

2 · sheet metal forming process pdf

3 · sheet metal bending process pdf

4 · metal forming processes pdf

5 · metal forming processes juneja pdf

6 · forming process in sheet metal

7 · drawing metal forming process

Find trim coil metal siding trim & soffit at Lowe's today. Shop metal siding trim & soffit and a variety of building supplies products online at Lowes.com.

This document provides information on various sheet metal forming processes. It discusses the characteristics of sheet metal and tests used to determine formability. The main .Sheet Metal Forming Sheet metal forming is a process that materials undergo .Sheet metal forming process Chapter 7 - Download as a PDF or view online for free.

Sheet Metal Forming Sheet metal forming is a process that materials undergo permanent deformation by cold forming to produce a variety of complex three dimensional shapes. The process is carried out in the plane of . Sheet metal forming operations include bending, stretching, deep drawing, and other processes where sheets are formed. Bending involves shaping a straight length into a curve and can be done using presses or rolls.Objectives. By the end of today you should be able to. .describe different forming processes, when they might be used, and compare their production rates, costs and environmental .

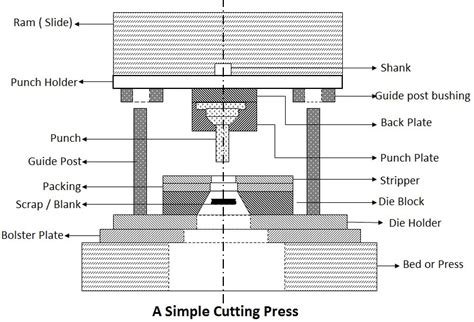

Manufacturing Engineering Technology in SI Units, 6th Edition Chapter 16: Sheet-Metal Forming Processes and Equipment Presentation slide for courses, Sheet Metal Forming Deep drawing. .Shearing Process that involves cutting sheet metal by subjecting it to shear stresses, usually between a punch and a die.

Manufacturing Engineering Technology in SI Units, 6th Edition Chapter 16: Sheet-Metal Forming Processes and Equipment Presentation slide for courses, Sheet Metal Forming Deep drawing. . Sheet metal forming process Chapter 7 - Download as a PDF or view online for free. Sheet Metal Forming Process and Their Application. Sheet metal forming process is carried out in the plane of the sheet by tensile forces with a high ratio of surface area to thickness. The high rate of production and .

sheet metal stamping process pdf

This document discusses sheet metal processes. It begins by defining sheet metal working as a chipless manufacturing process that forms various components from sheet metal using punching and other forming .Sheet metal forming process Chapter 7 Introduction Sheet metal forming operations produce a wide range of consumer and industrial products, such as metal desks, appliances, aircraft fuselages, car bodies, and kitchen utensils. Sheet-metal forming also called press working, press forming or stamping, is among the most important of metalworking processes, dating back to . 1) Incremental sheet forming is an innovative metal forming process where a spherical tool is used to push a sheet into a desired shape without the need for dies. 2) The document provides an overview of the . Group 9 Presentation. Sheet-Metal Forming Processes. Scott Currie Jared Adams Taylor Grisham Yien- Sheng Ao Joe Butner. Extrusion and Drawing of Metals. Definitions. 1.81k views • 90 slides. SHEET-METAL FORMING PROCESS Ch # 16. SHEET-METAL FORMING PROCESS Ch # 16. Introduction Shearing Sheet Metal Characteristics Test Methods for .

1. SHEET METAL PROCESSES Sheet metal characteristics - Typical shearing operations, bending and drawing operations – Stretch forming operations –– Formability of sheet metal – Test methods – Working principle and application of special forming processes - Hydro forming – Rubber pad forming – Metal spinning – Introduction to Explosive forming, Magnetic . Fine blanking Sheet Metal Forming Processes 34/7 8. MUHAMMAD TALHA NAWAZ (2K16-MET-15) 9. Shearing Dies Because the formability of a sheared part can be influenced by the quality of its sheared edges, clearance control is important. In practice, clearances usually range between 2% and 8% of the sheet’s thickness; generally, the thicker .

17. Cupping test : The sheet metal specimen is clamped between two circular flat dies and a steel or round punch is pushed hydraulically into the sheet metal until a crack begins to appear on the stretched specimen Fig 16.13 (a) A cupping test (the Erichsen test) to determine the formability of sheet metals. (b) Bulge-test results on steel sheets of various widths.The .

Metal forming processes are used to shape metals into useful products. Rolling is the most common forming process and accounts for around 90% of metal forming. It involves passing metal between rolls to reduce thickness or change cross-section. Forging uses dies and compression to shape hot or cold metal. Sheet metal working involves cutting, bending, drawing, and other forming operations to shape metal sheets. The processes include shearing, blanking, and punching, with various tools like punches and dies. Clearance, punch and die sizes, angular clearance, and stripper usage are crucial factors in achieving precise cuts. Fine blanking requires special . Sheet Metal Working & Process 2/17/2016 Compiled & Edited by SIVARAMAN VELMURUGAN 12 Sheet Metal Forming Process Large group of manufacturing processes in which plastic deformation is used to change the shape of metal workpieces. The tool, usually called a die, applies stresses that exceed the yield strength of the metal The metal takes a .

Cross-section of a bar, rod, or wire is reduced by pulling it through a die opening Spring 2005 Manufacturing Processes Sheet Metal Working Processes 1- Bending. Straining sheet metal around a straight axis to take a permanent bend Spring 2005 Manufacturing Processes Sheet Metal Working Processes 2- Drawing. Forming a flat metal sheet into a . 30. Drawing Sheet metal forming to make cup‑shaped, box‑shaped, or other complex‑curved, hollow‑shaped parts Sheet metal blank is positioned over die cavity and then punch pushes metal into opening Products: beverage cans, ammunition shells, automobile body panels Also known as deep drawing (to distinguish it from wire and bar drawing) ©2007 John .

SHEET-METAL FORMING PROCESS Ch # 16. Introduction Shearing Sheet Metal Characteristics Test Methods for Formability of sheet metals Bending sheet and Plate Common Bending Operations Tube Bending and Forming Stretch Forming Deep Drawing. . An Image/Link below is provided (as is) to download presentation Download Policy: Content on the site .Title: SheetMetal Forming Processes 1 Sheet-Metal Forming Processes 2 Sheet-Metal Forming Processes 3 Aluminum Two-Piece Beverage Cans. FIGURE 7.77 Aluminum two-piece beverage cans. Note the fine surface finish. Source Courtesy of J. E. Wang, Texas AM Univerity. 4 Metal-Forming Process for Food and Beverage Containers

sheet metal processes pdf

This document discusses various sheet metal forming processes including cutting, bending, drawing and other operations. It defines sheet metalworking as including cutting and forming thin sheets of metal between .%PDF-1.4 %âãÏÓ 663 0 obj > endobj 685 0 obj >/Filter/FlateDecode/ID[704E8A5A77AA90E0E45753C1AAABDACC>]/Index[663 39]/Info 662 0 R/Length 112/Prev 3172114/Root 664 . An Image/Link below is provided (as is) to download presentation Download Policy: . Sheet metal forming is a process that materials undergo permanent deformation by cold forming to produce a variety of complex three .Introduction to Metal Forming Technology : Download: 2: Classification of Metal Working Processes : Download: 3: Behavior of Materials : Download: 4: Failure of Materials . Analysis of wire drawing and tube drawing processes : Download: 37: Sheet metal operations-I : Download: 38: Sheet metal operations-II : Download: 39: Powder metallurgy .

Bending is a metal forming process in which a force is applied to a piece of sheet metal, causing it to bend at an angle and form the desired shape. 7. Two common bending methods are: V-Bending Edge bending V-Bending: The sheet metal blank is bent between a Vshaped punch and die.Sheet Metal Forming Processes. Sheet Metal Forming Processes. Introduction. Ratio – Surface Area:Volume is very high for sheet metal process. Plates – thickness > 0.25 inches Boilers, bridges, ships, etc. use relatively thick plates Usually sheet forming is done on relatively thin material. Shapes can be of various size. 649 views • 11 .Chap 2 , sheet metal – p. 1 Sheet Metal Forming Processes • involves workpieces with a high ratio of surface area to thickness • plates, thickness > ¼ inch • sheets, thickness ≤ ¼ inch • typical items produced by sheet-metal forming processes: metal desks appliance bodies . hubcaps aircraft panels . beverage cans car bodies

1. METAL FORMING PROCESSES Hot working and cold working of metals – Forging processes – Open, impression and closed die forging – Characteristics of the process – Types of Forging Machines – Typical forging operations – Rolling of metals – Types of Rolling mills - Flat strip rolling – Shape rolling operations – Defects in rolled parts - Principle of rod and .Metal forming processes Metal forming: Large set of manufacturing processes in which the material is deformed plastically to take the shape of the die geometry. The tools used for such deformation are called die, punch etc. depending on the type of process. Plastic deformation: Stresses beyond yield strength of the workpiece material is required. Incremental sheet forming (ISF) is a metal forming process that uses localized deformation from a tool to form a sheet of metal into a 3D shape through a series of small increments. ISF has potential advantages over other sheet metal forming processes as it does not require dies, allows for localized production and reworking, and uses lower . Rolling presentation • Download as PPTX, PDF • 50 likes • 19,625 views. HIMANSHU GUPTA Follow. This document summarizes the metal forming process of rolling. It describes how rolling works by passing metal between rolls, subjecting it to compressive and shear stresses. . 7 • Hot rolling is used mainly to produce sheet metal or simple .

Group 9 Presentation Sheet-Metal Forming Processes Scott Currie Jared Adams Taylor Grisham Yien- Sheng Ao Joe Butner. Extrusion and Drawing of Metals. Definitions Extrusion is defined as the process of shaping material, such as aluminum, by forcing it to flow through a shaped opening in a die. Extruded material emerges as an elongated piece with the .

metallic pleated fabric

metallic organza tulle fabric

Trio Sheet Metal Works Co Inc is a family-owned and operated company specializing in ductwork fabrication and installation for commercial and industrial air conditioning, heating, and ventilation. They have been in operation since 1983 and are based in Amityville, NY.

sheet metal forming process ppt|forming process in sheet metal