galvanized sheet metal comes in several different thicknesses called the Galvanized sheet metal comes in several different thicknesses, called the _____ of the metal. Get the best deals for Antique Metal Box with Handle at eBay.com. We have a great online selection at the lowest prices with Fast & Free shipping on many items!

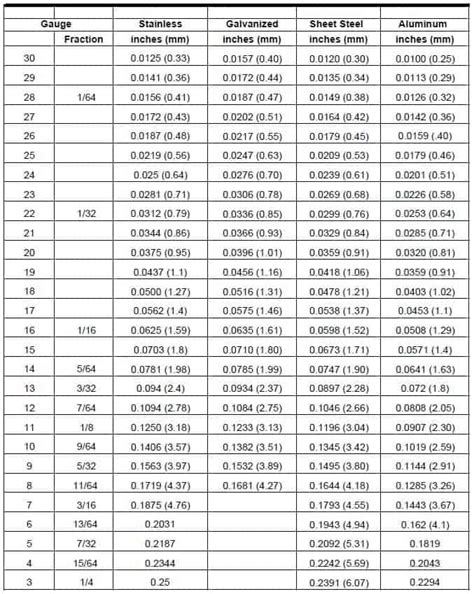

0 · sheet metal thickness chart printable

1 · sheet gauge to mm chart

2 · metal gauge thickness chart pdf

3 · gi sheet thickness chart

4 · gauge thickness chart sheet metal

5 · galvanized sheet size chart

6 · galvanized gauge thickness chart

7 · 12 ga steel thickness inches

$54.00

Galvanized sheet metal comes in several different thicknesses, called the _____ of the metal.

Galvanized sheet metal comes in several different thicknesses, called the _____ .Galvanized sheet metal comes in several different thicknesses, called the _____ of the metal.Galvanized sheet metal comes in several different thicknesses, called the _____ of the metal.Galvanized sheet metal is a steel sheet coated with a protective zinc layer, which helps prevent rust and corrosion. This coating plays a crucial role in enhancing the material’s durability and .

What are the Different Types of Galvanized Metal Sheets? What are the Variations in Thickness and Gauge? As I looked into the galvanized metal sheets, I came across several . Sheet sizes also come in multiple thicknesses. Sheet metal thickness is measured in gauges; the higher the number, the thinner the sheet metal. The most commonly-used sheet metal sizes range from 26 gauge .

sheet metal thickness chart printable

Galvanize sheet metal comes in different thicknesses, commonly expressed in gauge or decimal inches. The thickness can range from thin gauges (e.g., 26 gauge or 0.0187 inches) to thicker . What makes galvanized sheet metal a preferred choice for various industries? This article dives into the properties, types, and applications of galvanized sheet metal, revealing its effectiveness in rust prevention and .What is Galvanized Sheet Metal? Galvanized sheet metal is a sheet of steel that has been coated in zinc to make it resistant to corrosion. Because steel is made of iron, it will quickly rust when exposed to moisture, and over time that rust .

The thickness of the zinc coating is a critical factor in determining the durability of the galvanized metal. For increased corrosion resistance, a thicker coating is recommended for applications .【Solved】Click here to get an answer to your question : Galvanized sheet metal comes in several different thicknesses, called theStudy with Quizlet and memorize flashcards containing terms like When steel is galvanized, the galvanizing process is a form of a(n)_?, An advantage of using galvanized sheet metal over other materials when assembling a duct system is it_?, When steel is .How is Sheet Metal Galvanized? Steel sheet metal can be galvanized using a few different techniques. These include: Hot-dip galvanizing: This is a popular technique that has been used for more than 100 years, and it involves .

Aside from the thickness of the sheet metals, they also come in different sizes. Although there is a range of standard sheet metal sizes, the most common ones are 36”x 96”, 36”x 120”, 36”x 144”, 48”x 96”, 48”x 120”, and 48”x 144”. . This means you may purchase an 18-gauge metal sheet in several different sizes .

Iron is not steel. Galvanized sheet metal for air ducting is cold rolled steel sheet with a coating of zinc. For sheet metal, so far as I know, it is electroplated - not dip coated. It is called 'galvanized' because the zinc and steel is preserved by sacrificing the zinc - .Study with Quizlet and memorize flashcards containing terms like Sheet steel is available as coated or uncoated, A digital micrometer indicates the measurement of the barrel and thimble and the digital readout, The _____ gauge system is commonly used for Sheet Metal and more. . Galvanized sheet metal is available in 18 inches and 54 inches .Galvanized sheet is a metal material produced by coating steel sheet with zinc. The galvanizing process significantly increases the corrosion resistance of steel sheet. Galvanized sheet is used in a variety of applications. Buying Galvanized Sheet. To buy galvanized sheet, you first need to determine the thickness, width, and length you need.Galvanized sheet metal comes in several different thicknesses, called the _ of the metal. gauge. Each foot of duct offers a known resistance to airflow which is called _. friction loss. . The forced-air system is different from a natural-draft system, where the air passes naturally over the conditioning equipment. .

Although the usage area is different for each sector, it is among the products that we come across in many sectors. Galvanized sheets, which are among the most requested products from our factory in the current year, pass through the production stages in our iron-steel factory and are offered to you with the quality of Şen Metal at the most . As I looked into the galvanized metal sheets, I came across several differences in the thickness and gauge attributes, which depend on the desired use and manufacturing processes. In these cases, a thickness is expressed in mils (thousands of inches) or gauges; a low gauge number means a thicker sheet.

Check environmental conditions, desired life span for galvanized steel, and load-bearing capacity. These things will help you to find the required thickness and type of galvanized steel. Galvanized Steel comes in two coats. Hot-dip-coated galvanized steel is . For harsher conditions, galvanized steel’s extra defense is better. For milder environments or where aesthetics are important, galvannealed steel can be a good alternative. Cost. When it comes to cost, galvanized steel is generally cheaper than galvannealed steel. This is because galvanized steel requires a simpler manufacturing process.When steel is galvanized, the galvanizing process is a form of a(n) _____. Is resistant to corrosion. An advantage of using galvanized sheet metal over other materials when assembling a duct system is it _____. Gains tensile strength. When steel is rolled while it is cold, it _____. Acme, or pipe lock . Galvanized Steel: Protected by a zinc coating, galvanized steel resists corrosion and provides a clean finished appearance. Thicknesses: Brake machines are designed to handle varying metal thicknesses, typically expressed in gauge or millimeters. Thin Metal (up to 10 gauge): Can be bent using a standard box brake.

Study with Quizlet and memorize flashcards containing terms like What are the 11 different kinds of typical sheet metal repairs?, What do you use a octagonal patch to repair?, What are the 4 basic steps to repair using a octagonal patch? and more. . Diameter: 3x the thickness of the thickest sheet. Length: material thickness + 1.5 times the .

When it comes to metal materials, galvanized metal sheets and stainless steel are two popular options that offer different advantages and disadvantages. Durability: Galvanized metal sheets are coated with a layer of . Plate stock is a form of flat metal or alloy that comes in a plate shape and is used in different applications and manufacturing processes. They can take different forms, which include flats, and sheets. Plate is a good raw material for sheet metal fabrication, machining parts, building materials, and floor fabrication.

The table below is an easy to understand resource that allows you to determine gauge by metal thickness in both inches and millimeters, for standard steel, stainless steel, galvanized steel, aluminum, copper, and brass. There are several different gauge systems used today, with specific gauge designations for specific metal types.The Discovery of Galvanization: The process of galvanization, which involves the application of a thicker layer of zinc to steel, was discovered by Luigi Galvani, an Italian scientist, in the late 18th century. Galvani observed that when two dissimilar metals were connected and immersed in an electrolyte (such as saltwater), a protective layer formed on the metal that was more .

The substrates used for pre-painted metal can be cold rolled steel, galvanized steel, hot rolled steel, galvalume, stainless, and aluminum.Basically, anything that can be manufactured in coil form is a possible input substrate for painting; however, the costs of some substrates generally keep them from being widely used.Most of the metal .

In the US, most sheet metal is sized by gauge. The bigger the gauge, the smaller the thickness. It is different for different metals. If you're making a pellet stove of your own, then you'll probably want something fairly thick, like 11 gauge (which is roughly 1/8" thick in stainless) or thicker.

Sheet metal thickness is an important factor in fabrication. Metal fabrication shops often work with raw stock sheet metal from 0.02” to 0.250” thick. What does that mean for you, the customer?Sheet metal tools. 10 terms. therealjkennedy Teacher. Verified questions. physics. The two blocks are moving with an initial speed v v v. (a) If the system is frictionless, find the distance d d d the blocks travel before coming to rest. (Let U = 0 U=0 U = . Thickness: The thickness of a galvanized coil refers to the measurement of its gauge or how thick the steel strip is. It is typically measured in millimeters or inches. Galvanized coils are available in a wide range of thicknesses, often ranging from 0.12mm to 5.0mm, depending on the application and customer requirements. The layer of zinc acts as a barrier between the steel and the environmental conditions preventing it from oxidizing. Now, when the galvanized steel is manipulated to form sheets of steel, the end product is called galvanized steel sheets. Galvanized steel sheets are also produced by immersing ordinary steel sheets directly into hot molten zinc.

sheet gauge to mm chart

$9.99

galvanized sheet metal comes in several different thicknesses called the|sheet metal thickness chart printable