how to weld sheet metal with flux core wire To best weld with flux core, select the correct wire and equipment, clean your metal surface, adjust the welder settings to suit your task, practice good technique with steady motion, and always wear appropriate safety gear. The metal end of a tape measure is loose to account for the thickness of the hook end. This movement allows accurate measuring whether you are measuring internally or externally. The metal end of the tape measure varies but is usually around 1-2mm in thickness.

0 · yeswelder flux 135 settings chart

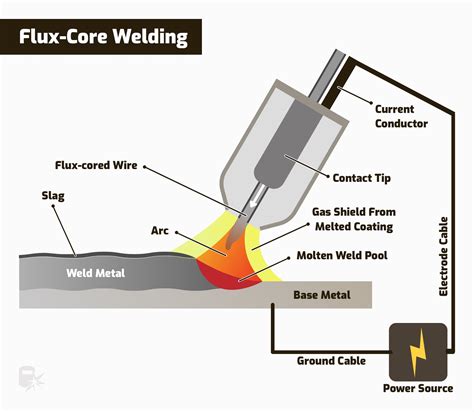

1 · flux wire welding basics

2 · flux core wire welding techniques

3 · flux core wire welding instructions

4 · flux core wire welding basics

5 · flux core welding wire diagram

6 · flux core welding tricks

7 · flux core welding for dummies

You may need a wide toe box but buying quality work boots doesn’t depend on a toe box alone. The toe box width is a part of finding the correct size. Here are some other aspects to factor in when making your selection. 1.) Brand Select a reputable brand for . See more

Today we will be going over some tricks to weld thin gauge sheet metal like body panels while avoiding wrapage. I go over 2 different techniques and several tips so make sure you watch til.

#welddotcomLets weld some thin material with flux core!Join Weld.com today, get member’s perks and support the community! https://www.youtube.com/channel/UCM.

yeswelder flux 135 settings chart

flux wire welding basics

To best weld with flux core, select the correct wire and equipment, clean your metal surface, adjust the welder settings to suit your task, practice good technique with steady motion, and always wear appropriate safety gear. In this guide, we're diving deep into the art of flux core welding, breaking down the process step by step. Whether you're a greenhorn or a seasoned welder, this guide is your ticket to unlocking the secrets of . How to Weld Thick to Thin Metal with Gasless Flux Core Wire - Trying out some TIps and Tricks for welding thick to thin metal with gasless flux core wire usi.Lastly, do not try to use flux cored wires for thin metal sheets as they pass more heat to the base metal. Flux-cored arc welding (FCAW) This is another option for welding a 20-gauge metal sheet but does not work as well as the MIG. .

Wondering if it's possible to butt weld automotive sheet metal with a flux core welder? This video can help answer that question by using a Harbor Freig. Hands on welding with the harbor freight titanium flux 125. All the basics of flux core wire welding with FCAW-s self shielded wire are covered. Even if yo.The Welding Action. When welding sheet metal with flux-cored wire, you will need to move quickly through the weld. Try to keep your working angle at around 10°, dragging the pool rather than pushing it. If welding a T-joint, aim a little higher than you would with solid wire. The flux-cored wires have a more fluid welding pool. I recommend welding with the welder set to max, with the wire speed at about 5-6. Using a zigzag motion across the weld. Just make sure when you are doing th.

Flux Core Welding Sheet Metal uses gas-less flux core wire which means you don’t need gas. The wire contains “Flux” which will burn while you weld. The flux acts as a protective gas that stops the weld from becoming contaminated. Tons of folks will tell you not to flux core weld thin sheet metal and here’s a list of their responses: Its . I've made videos in the past about welding 22 or 24 gauge steel with gas-less flux core wire, I thought I'd give it one more shot here after being a little m. The complete process to set up and run welds with the Flux Cored Arc Welding (FCAW) process, also referred to as gasless MIG.****Affordable self-paced weldin.

Noticed a huge difference in quality vs AC like the welder came. Much better "sizzle", less spatter etc. I had always been using the wire that came with the machine but read about that wire sucking. Saw Blue Demon flux core got great reviews on Amazon so I bought a 2# roll. Also recently was looking into the Blue Demon stainless wire Many metal inert gas (MIG) welding machines are capable of flux-core welding, but unlike the MIG or gas metal arc welding (GMAW) process, an external shielding gas is usually not required to protect the weld from contaminates when welding with flux-cored wire. In self-shielded flux-core welding, the welding wire has a core containing flux, a . Self-shielded flux-cored welding is a wire welding process in which a continuous hollow wire electrode is fed through the welding gun into the weld joint. It differs from MIG welding in that it doesn’t require an external shielding gas, such as carbon dioxide or argon, to protect the weld pool from contamination. . Metal preparation for .

If you're wondering if you can use a flux core, gasless MIG welder for auto body work, this video will answer that question so that you can make an informed . This Video show the process to Repair a 2 inch hole inside a truck box. Part 1 is the fabrication of the sheet metal, Part 2 is the welding (using wire feed. To weld sheet metal with flux core wire, you will need a welding machine that is capable of running flux core wire. You will also need a welding gun, a ground clamp, and a spool of flux core wire. In addition to these basic . In this follow up to an earlier video, David covers ideal machine settings, weld positions, and contact tip to work distance using Lincoln NR-211 self-shield.

flux core wire welding techniques

Single spot weld, move etc. till panel welded in. I have the the .024 wire and c25 also, it is higher quality, but when just doing spots the flux core was acceptable if set up properly. I did fight pin holes more with the flux core. Even small stitches it was no contest for the C25 though. In my opinion flux core limited to spots only on thin . How To Fill metal Gap or hole or Crack Using Wire Feed flux core Welder.this video shows how to fill a gap or hole on the metal, this is a shovel has about. Im installing floor pans in my 86 cutlass and I have to add some metal to the pan. so while I was at it I thought I show you some ways of spot welding and bu. With the right equipment and a focus on safety, you can dive into the world of Flux Core Welding with confidence and take your welding skills to new heights. Flux Core Welding Tips and Techniques for Beginners. Flux Core Welding offers an array of tips and techniques that can significantly improve the welding experience, especially for beginners.

The week we are going over how to weld thin metal like exhaust systems and turbo manifolds. The concept is actually fairly simple and you could be welding li. This video was a tough one. I tried to find the easiest way to weld thin sheet metal with flux core. Flux core is usually used for heavier metals and is not .

In this video, we'll teach you how to improve your flux core welding skills so that you can start welding without difficulty. By the end of this video, you'l.

A Chicago Electric Flux Core 125 Welder from Harbor Freight is used to weld an automotive patch panel into place fixing a lower fender rust hole. Special th. Today we're flux core welding sheet metal. Last time we did a thin gauge flux core welding video we used 1/8" and got completely hammered for it not being th.Testing Lincolns Inner shield 211-MP on galvanized. David explains how to weld with FluxCore on thinner metal. For a longer, more detailed version of this video, please check out: https://youtu.be/KLfEPH9dTCQ..

flux core wire welding instructions

flux core wire welding basics

flux core welding wire diagram

flux core welding tricks

Manufacturer: Wilder; Model: 1624 Slitter; Capacity: 16 Ga Single Wheel Slitter; Electrics: 110V; 24" Throat To Cut 48" Wide Metal In Half; Adjustable Gauge Bar; Weight: 450 LBS. Dimensions: 49"L X 30"W X 34"H; Approx. New List Price: $3,200.00; Location: CCR Warehouse

how to weld sheet metal with flux core wire|flux core welding for dummies